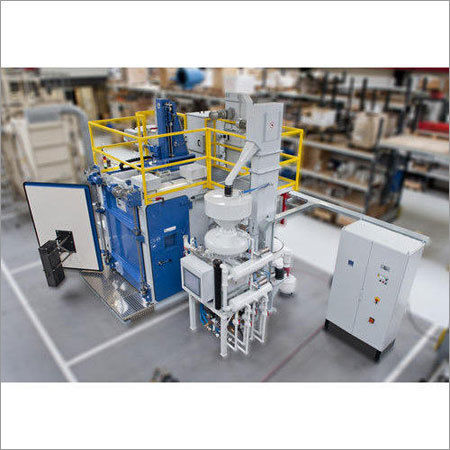

Shot Peening Machine For Sale

Enhancing Workpiece Floors with Shot Blasting Machines: An Complex Exploration

Shot blasting machines have surfaced as indispensable tools for the surface treatment of various elements, including stainless steel and iron diffusion. Regarded as the greatest ally in workpiece surface processing, these types of machines play a pivotal role in achieving optimal surface finishes and enhancing product quality. Let's delve into some sort of comprehensive introduction to picture blasting machines, masking their classification, framework, functions, and unquestionable advantages.

Classification and Structure:

Shot blasting machines can be found in numerous structural configurations, every tailored to specific applications. Common classifications include drum-type, string plate type, cart type, squirrel-cage type, and rotary stand type. Despite structural variations, shot blasting machine accessories continue to be relatively consistent. Commonly, a shot blasting machine comprises several main components:

Impeller Head: Responsible for casting shots inside a specific course using high centrifugal force generated with a high-speed rotary vane wheel.

Shot Getting, Separation, and Vehicles System: Collects and even transports shots with regard to reuse while isolating debris.

Supporting Physique: Sustains continuous functioning and rotation in the cleaning process.

Particles Pelletizing System: Ensures a clean working environment by handling dust particles.

Capabilities of Shot Blasting Machines:

Shot blasting machines serve multi-dimensional functions crucial in order to various industries:

Surface Cleaning: Eliminates burrs, rust, and range cinder from metal castings, ensuring maximum surface quality.

Finish Preparation: Removes area contaminants to reinforce finish adhesive force, enhancing the durability plus longevity of films.

Stress Induction: Introduces controlled surface challenges to improve exhaustion life and general strength of workpieces.

Strengthening peening machines : Improves the strength and dependability of components, catering to industries like aerospace, automobile, modern aviation, and tractor making.

Advantages of Shot Blasting Machines:

The widespread adoption associated with shot blasting equipment could be attributed to several compelling advantages, including:

Enhanced Surface area Quality: Achieves uniform surface finishes and removes imperfections, making sure product integrity.

Enhanced Productivity: Streamlines surface treatment processes, top to faster turnaround times and enhanced efficiency.

automated shot peening machines : Reduces labor fees and material wastage related to manual surface preparation methods.

Versatility: Adaptable to some sort of wide range associated with workpiece sizes, designs, and materials, supplying versatility and flexibility in production.

Throughout summary, shot blasting machines represent the cornerstone in modern manufacturing, offering unequalled capabilities in area treatment and enlargement. From surface cleanup to stress induction, these machines carry on to revolutionize sectors by elevating product quality and overall performance standards.